|

|

Post by tar12 on Oct 13, 2010 15:41:28 GMT -5

Thats what I am talking about! ;D |

|

|

|

Post by deadeye on Oct 13, 2010 16:09:30 GMT -5

like davew ,i get none or next to none copper fouling with no swabbing.also pac #1 likes 4shots to get in the .5-.7moa groove,pac #2 likes 8 for some reason. on both of mine you start to get what i call slip & grip or chattering down the barrel somewhere around 15-20shots deep,after 30 1 carb patch,1dry & run the foulers again. i would call my seating pressure around 50-65lbs fyi,back to the thread hopefully for harley's success report.

|

|

|

|

Post by Jon on Oct 13, 2010 16:52:05 GMT -5

All interesting but what does this have to do with an adjustable die? Which I happen to think is a definate step forwards. Sorry if I'm stepping on anyones toes. Everything said was informative but I don't see what it has to do with the performance of the die which I think is great.

Jon

|

|

|

|

Post by deadeye on Oct 13, 2010 19:09:30 GMT -5

jon,i think if threads twist so be it,sometimes they travel but imo if people post then their attention is on that thread they posted on/nothing new,i would not be here shooting great groups & at long distance i desired w/mz without this board & the many good people here,i look at this way if it was informative that is a plus for the recipient/jmho//spellcchek ;D ;D ;D

|

|

|

|

Post by tar12 on Oct 13, 2010 19:35:38 GMT -5

Jon, Are you referring to my posts? If you are,they having everything to do with this post! First off I find the concept of this adjustable die very intriguing and possibly worth my pursing.Hence the questions.IMO,any question or discussion regarding the end result of the use of this die is worth asking.Many times these post evolve to encompass every aspect of what is being discussed. It answers a lot of question for those wanting to know. There is a problem with sharing beneficial knowledge?  |

|

|

|

Post by Richard on Oct 13, 2010 19:52:25 GMT -5

Jon...........They are discussing the merits of the die such as being able to adjust the size of the bullet in relation to the degree of fouling or, no fouling that works best in their rifle. Sounds like a great die! On the other hand, I am somewhat leaning towards Rexxer's way of thinking. The knurled up bullet allows for good seating due to the "knurlies" ability to compress as they force their way into the groves. The die still has merit in that you can under size, knurl and then get a precise fit while still having some "knurlies" left for compression. (which would be a help with a fouled bore)

Richard

|

|

|

|

Post by deadeye on Oct 13, 2010 20:35:14 GMT -5

and also imagine resizing a .458 bo down in steps w/this die to fit a sabotless bore.possibilities!

|

|

|

|

Post by tar12 on Oct 13, 2010 21:36:34 GMT -5

and also imagine resizing a .458 bo down in steps w/this die to fit a sabotless bore.possibilities!  I like the way you think! ;D ;D |

|

|

|

Post by Dave W on Oct 13, 2010 22:03:13 GMT -5

|

|

|

|

Post by tar12 on Oct 13, 2010 22:26:11 GMT -5

Thanks! How did I miss that?  ;D |

|

|

|

Post by Al on Oct 14, 2010 3:04:27 GMT -5

jackets are pretty thick on the BO's, dunno if they'd obutrate so well, but if any of you want to give them a try, I can take them down to about .452 with my dies and you can finish them off to the size you need.

|

|

|

|

Post by Harley on Oct 14, 2010 22:21:50 GMT -5

I'm just now coming in from testing the die on the range; I definitely do have some interesting data and will try to put it together for posting sometime Friday, Saturday at the latest.

Harley

|

|

|

|

Post by northny on Oct 15, 2010 12:16:52 GMT -5

Now thats a teaser if I ever heard one! glad you got a chance to shoot, and I look forward to the results. details at 11.

|

|

|

|

Post by Jon on Oct 15, 2010 14:32:53 GMT -5

Harley. A big teaser.

And to others that were bothered about my post. I apologize I'm concerned about the efficiency of the die it self. I thought that is what we were discussing I did say everything was interesting.

Jon

|

|

|

|

Post by Harley on Oct 15, 2010 15:35:05 GMT -5

I haven't been able to copy both the following text (from Word) and the images from Photobucket at the same time; so, I'll post the text, then post the target images in the next frame.

______________________________________________________

As outlined in my Reply #11, above, my testing method was to fire six fouling shots before shooting comparison three-shot groups using 12/47 SR4759/A2015, the CCIM primer, a dry wool wad and the 275 gn Parker BE: one with new Parkers sized through the Swing-Lock smooth die, and the other with previously sized Parkers (.448” Lee die), heavy knurling and a final single pass – as a check on diameter - through the Swing-Lock die set at the same diameter as for the new Parkers.

My first fouling shot was with a 300 gn Hornady XTP, slightly larger re-sized in diameter than the rest of the following bullets because I wasn’t sure it would, at the “test” diameter, seal in the clean barrel tightly enough to ensure ignition. It still loaded very easily, though, and ignition was complete.

I followed that shot with my regular between shot routine of one patch with six dots of Butch’s solvent (I used Butch’s only because I have a lot of it and don’t think it’s a very efficient solvent for cleaning my rifle barrel) in and out, followed by one dry patch in and out.

The next fouling load, sized to the same diameter as all the subsequent bullets, was so tight that I barely was able to press it in the barrel the length of the short starter. From there, I had to hammer it home with a rubber mallet and short lengths of ramrod. It did fire and the POI was where it should be.

At that point I thought my day was over, since one of my worst case scenarios had come to pass. As a desperation approach, I tried a new between shot routine: I stacked two patches together, placed 10 dots of solvent on the top patch (it soaked through to the second patch), ran the first patch in and out, turned it over and ran it, again; then repeated with the second patch. I followed that with a dry patch, in and out, then turned it over for a second pass, and repeated that with a second dry patch.

It worked: I was then able to shoot the remaining four fouling XTP’s and the two three-shot comparison groups.

RESULTS:

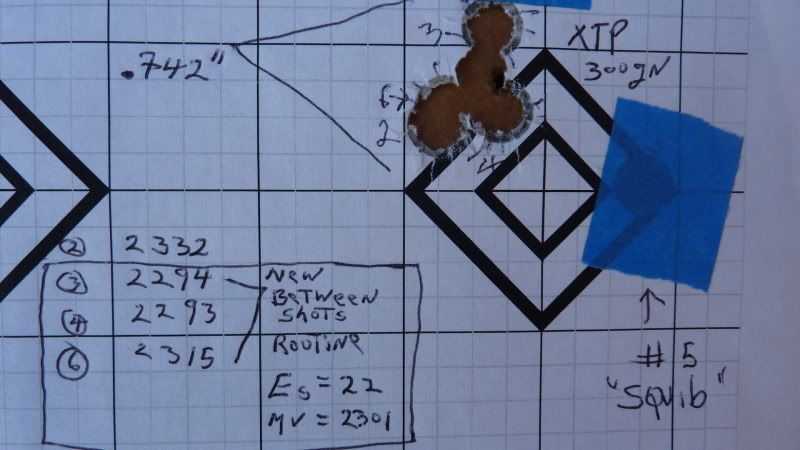

The first target represents the fouling shots. The load was the 300 gn XTP, 53.5 gns of H4198, a dry wool wad and a non-magnum W209 primer. I covered shot number one because it was fired with the larger diameter first bullet. I also covered shot #5, which was a squib report and fell outside the group. The remaining four shots, grouping at .742” and 2301 fps, with an extreme spread of 22 fps, would make a lot of people happy as a final hunting load.

The next two targets, shown together for comparison purposes, were controlled for every variable other than bullet resizing method. The left hand target was fired with a single pass through the Swing-Lock die of the smooth new Parker; the right target with the previously sized, knurled and “check” pass through the Swing-Lock die set at the same diameter as the first target group.

DISCUSSION;

1. My older targets, not seen here, shot with bullets Lee die sized and knurled, at the same ambient temperature, averaged 2307 fps muzzle velocity with an extreme spread in the teens. Today’s target, the one on the right, differing only in having had a final check through the Swing-Lock die and a different between shot routine, averaged 2381 fps muzzle velocity. That is a significant increase. (The seating effort seemed roughly the same as with the older between shot routine.) Today’s group also was almost three times larger than I’m used to shooting with the knurled bullets. I can’t explain the difference because I have at least two confounding variables: the between shot routine and the final check through the Swing-Lock die. The extreme spread of only 19 fps testifies to the consistency of the results.

2. The group on the left, the single-pass-through-the-Swing-Lock-die of new bullets, is excellent at .507”. Again, though, the muzzle velocity (2399 fps) is almost 100 fps faster than previously attained. The extreme spread of 13 fps is reassuring. Seating pressure was very smooth and only moderately difficult.

3. As previously stated, the groups were shot simultaneously by shooting alternate targets in succession (shots 1-3-5 on the first target and 2-4-6 on the second). That should have removed any differing effects of fouling accumulation between the two groups.

4. On the right hand target, the one with the knurled bullets, shot number six spoiled the group; shots 2 and 4 impacted tightly and at roughly the same POI as the group in the left target. Note that shot number 6 has the lowest muzzle velocity of the group at 2370 fps. In my experience the lower MV results in a higher impacted shot at 100 yards. I’m not sure, though, that the MV explains the higher strike since the total extreme spread is only 19.

5. I made it a practice to discard the two solvent patches used after every shot, but retained the two dry patches for use as solvent patches after the next shot. That meant I was using up a total of two patches per shot. The entire between shot routine took no more than two minutes, probably less.

6. After the solvent and drying patches I used a re-circulating barrel cooler of my own design to bring the barrel temperature below ambient, then waited a minute for the temperature to stabilize before reloading.

7. Both the previously knurled and the new Parker’s loaded smoothly with no chatter; the new Parker’s loaded especially smoothly and seemed to become even more so from bullet to bullet.

8. The higher muzzle velocity of the smooth bullet may or may not be statistically significant compared to the knurled bullet; if it is significant it may indicate better obturation of the smooth bullet, which would be a surprise to me.

9. The knurled bullets are a lot more forgiving of differences in fouling than are the smooth bullets. A long time back, I speculated that knurling resulted in a more malleable bullet surface; others on this thread have agreed.

FUTURE TESTING

One group does not prove anything; I’m very satisfied with the results of the Swing-Lock die, though, and will not run any more comparisons between using it alone and using it in conjunction with knurled bullets.

I can live with this between shot routine, but will probably experiment with closing the die a little at a time to find a point at which the bullet diameter is small enough that the between shot routine is reduced to one wet and one dry patch.

I also want to verify the higher obtained muzzle velocities.

CONCLUSION

Tom Post is onto something good; his die is far superior to even a three-die collection of Lee dies. With the Swing-Lock die you can dial an infinite amount of diameter changes in almost exact steps; with the Lee die what you see is what you get; you can attempt to lap the Lee dies, but will not enjoy the ability then to reverse what you’ve done.

I’ve received enough PM’s in the last few days to lead me to believe that there is a market for the Swing-Lock in several calibers; I don’t know what number of orders Tom would have to have before making other calibers available. I do believe he is following this thread and invite him to comment on all the questions raised by forum members who have posted.

Harley

|

|

|

|

Post by Harley on Oct 15, 2010 15:39:15 GMT -5

Fouling shots with XTP:  Comparison targets; the one-pass Swing-Lock target is on the left; the previously knurled target is on the right.  |

|

|

|

Post by Dave W on Oct 15, 2010 16:46:38 GMT -5

Excellent report and shooting, as usual.  Maybe the knurled bullet with a little load tweaking would shoot just as tight as the un-knurled bullet? Could the extra velocity be from using different lot numbers than what timed at 2307fps? Your results back my experiences with land sized Parkers, excellent accuracy. ;D |

|

|

|

Post by jims on Oct 15, 2010 17:07:58 GMT -5

I ordered mine yesterday for my .375. I did not ask how long it would take. When it gets here will be soon enough since I already have nearly three years invested in the project but it has been on the back burner for awhile.

Will report when I can.

|

|

|

|

Post by Richard on Oct 15, 2010 17:09:16 GMT -5

Nice report Loyd!

Richard

|

|

|

|

Post by Harley on Oct 15, 2010 18:09:29 GMT -5

DaveW, the knurled Parkers were from a previous batch I had done at the same time as all my other MV=2307 results, so that's not an explanation. This comparison group of 1.264" is made up of components identical to all my sub-moa groups out to 400 yards. The ONLY differences are the between shot routine and the final pass through the Swing-Lock die. Still, you may be right: If I keep the new between shot routine and use the Swing-Lock die for a check of knurled bullets, maybe I COULD further tweak that load; but what's the purpose? I could just go back to what I was doing successfuly before the Swing-Lock die.

I ideally would like to take a new Parker, run it once through the Swing-Lock die and go hunting; no more knurling, no more final passes through a check die. This one group says that's possible, I think. What I can improve on is the between shot routine, but I'm afraid that's going to be a long drawn-out affair of tweaking the Swing-Lock die, then going out to shoot, hoping the bullet will load after only one or two patches instead of four.

Thanks, Richard; good luck with your project, Jims.

Harley

|

|

|

|

Post by bigmoose on Oct 15, 2010 20:10:14 GMT -5

Harley,

Can the tool resize a Barnes 290gr .451 all copper bullet to 450.0 in one pass thru.

Thanks,

Marty

|

|

|

|

Post by tar12 on Oct 15, 2010 21:12:16 GMT -5

I ordered mine yesterday for my .375. I did not ask how long it would take. When it gets here will be soon enough since I already have nearly three years invested in the project but it has been on the back burner for awhile. Will report when I can. I believe this is your answer you have been looking for buddy! |

|

|

|

Post by Harley on Oct 15, 2010 22:31:59 GMT -5

Bigmoose, I've never resized an all-copper bullet, but I do know that .451 down to .450 is in the Swing-Lock's adjustment range, and I have found resizing with the Swing-Lock in a standard press is much easier (requires less force) than resizing with a Lee die in an arbor press.

Tom Post recommends a wax-based lubricant for the Swing-Lock; maybe it makes resizing easier than the old bullet lubricants I used to use.

Harley

|

|

|

|

Post by Jon on Oct 16, 2010 1:26:13 GMT -5

Harley. Great report as usual. Was the Lyman black bowder gold what you used for all the sizing?

Jon

|

|

|

|

Post by bigmoose on Oct 16, 2010 6:33:04 GMT -5

Harley,

Thanks for your answer, I started using bee's wax for resizing with the arbor press, but I think Lee's lub as well as Fly reel lub worked just as well I have resized a goodly amount.

I'll e-mail Mr. Post, with my question,

Have a fine weekend

Marty

|

|

|

|

Post by Jon on Oct 16, 2010 7:16:33 GMT -5

Bigmoose. I'm also interested in what Tom advises. He sent a sample of what he uses with my die I just havn't been able to find it yet. Thank you

Jon

|

|

|

|

Post by bigmoose on Oct 16, 2010 8:25:42 GMT -5

Jon,

I have found that resizing all cooper bullets are easier than jacketed one,s, I must add all I know about resizing I learned from Rick,

|

|

|

|

Post by swinglock on Oct 16, 2010 9:11:12 GMT -5

Harley,

Excellent reporting! I also appreciate and enjoy reading everyones comments.

To answer a few questions, either version of the die ( smooth or full form ) can be made in any caliber but for a full form die, a barrel drop must be available to make the sizing element. If a drop is not available a short piece can be cut from the rifles barrel if the customer is willing. The barrel would then be recrowned with exact precision.

For bullet lubrication, I have used the Lyman Gold bullet lube, Johnson's #140 Stik Wax, and bees wax mixed with vaseline just to soften it up some. No doubt there are many other lubes which will work. If a lube is not adequate bullets will require great force to push through.

The smooth die is indeed very useful as confirmed by Harley's report but, the full form die is something that deserves serious consideration per the following advantages:

1. A much better seal is produced because the bullets form fills the rifling grooves.

2. The bullets can be sized to load MORE EASILY while still having a much better seal.

3. Because of the superior seal, reliability of ignition is also better even with easy loading bullets.

4. Full formed bullets do not require the use of over powder wads. I never use wads with full formed bullets.

5. Because the bullets are automatically engaged to the rifling, high pressure is not required to assure obturation. Low pressure loads have produced equally good accuracy.

6. The bullets produce higher velocities with less pressure.

In .45 cal. using .458 dia. full form sized solid copper Barnes X, TSX or the 300gr polymer tipped, boat tailed SOCOM bullets great accuracy has been experienced plus all of the advantages Vs the other bullets. I have one customer shooting 1/4" groups at 100 yrds shooting the 300 gr Barnes SOCOM bullet at over 2900 fps.

Delivery for a die depends upon work load but I do my best to fit them in so the wait is short as possible.

I'm very happy to answer any questions.

Tom

|

|

|

|

Post by bigmoose on Oct 16, 2010 9:13:33 GMT -5

Jon I just tried sending Tom Post an E-Mail at both his address Swinglock.net Swinglock@Velocity.not AOL said invalid address?      ? HELP |

|

|

|

Post by Dave W on Oct 16, 2010 9:22:03 GMT -5

Tom, anyone full forming the .458 300gr Barnes Original and accuracy obtained? This is probably the most popular bullet among this crowd. Price on the full-form die ?

|

|