|

|

Post by smokepole50 on Nov 18, 2010 18:03:08 GMT -5

I am seeing some flame channel errossion in my new .50 Accura.

I have shot the rifle about 60 times and while looking at the BP under a microscope I can see metal being deposited on the shelf that the primer sets against. I thought it was burning from the 209 primer ignition but it is actually metal that has been erroded from the flash hole and has volcanoed at the primer end. The flash hole at the powder end still measures .031 maybe .032 and I see no noticable errosion on the powder side.

I have been considering installing a vent line in this BP but won't this just make the problem worse since the flash hole will be all that much shorter with the vent liner screw? I have been using Win. 209 primers so I guess I have the longest primers there are. Does anyone have any numbers on primer length?

My load, a 300gr Rem. .458 bullet in a Har. BCR sabot and 84gr weighed of BH209 is stout but I would think the 209 primer should hold up to that if it holds up to smokeless loads. Maybe my BP is to short allowing the primer to get slamed back against the receiver and conform to the firing pin bushing as it has been doing for some time. Yes, I get a nice flat head screw driver slot formed on the face of my primers. I just thought it was pressure but now I am wondering if it is a short BP. I will have to check it against the new and unfired .45 Accura at home. Something is not as it should be.

Smokepole

|

|

|

|

Post by smokepole50 on Nov 18, 2010 19:02:40 GMT -5

Well after a long talk with Dave D. I am going forward with the vent liner modification. I guess the CVA breech plug steel is not that tough when it comes to BH209 pressures. Hopefully a Lehiegh VL will last longer that 60 shots.

*********I would like to ammend this post and say that what I was seeing was most likely a bad case of carbon build-up. All BP's will wear out in time but in this case I believe it was premature of me to say this BP in question was bad after just 60 shots. Always take a drill bit and see if it is carbon build-up before you assume it is not.

Smokepole50

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 18, 2010 19:06:56 GMT -5

"the shelf the primer sits against"

Carbon build up.

I shoot a LOT of blackhorn and none of my plugs show erosion.

You can adjust the head space by installing an o ring and slowly drilling the primer pocket a bit deeper. I had adjusted my original accura's plug that way for a tight primer fit. Worked perfect too.

|

|

|

|

Post by grouse on Nov 18, 2010 19:18:22 GMT -5

You hafto expect that from CVA. I would really have a breech plug made for it. My Accura needed that done, but i sold it instead.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 18, 2010 19:23:03 GMT -5

oh im sure it did grouse  |

|

|

|

Post by smokepole50 on Nov 18, 2010 21:38:07 GMT -5

Well it's a done deal, the Lehigh vent liner is installed.

I can not believe how soft the BP metal was when I drilled and tapped it!

There is no wonder it erroded so fast with upper end loads.

I used successively sized drill bits to slowly reach .156 for the 10-32 threads. With the smaller bits the metal shaving came out as dust. It was like the inside of the BP was made of pot metal. Now I know it was not "pot metal" but it was very soft steal. To soft in my opinion, but it did make drilling and tapping it a breeze so I guess that is a positive. Maybe I should have a couple BP made for these rifles out of some tough steal. Is 18-8 SS soft???If I had BP's made out of 304 SS then I could adjust the head space so it would be perfect with a given primer. But 304 might not be the best choice either.

Any ideas on BP steal??

Smokepole50

|

|

|

|

Post by sabotloader on Nov 18, 2010 23:32:22 GMT -5

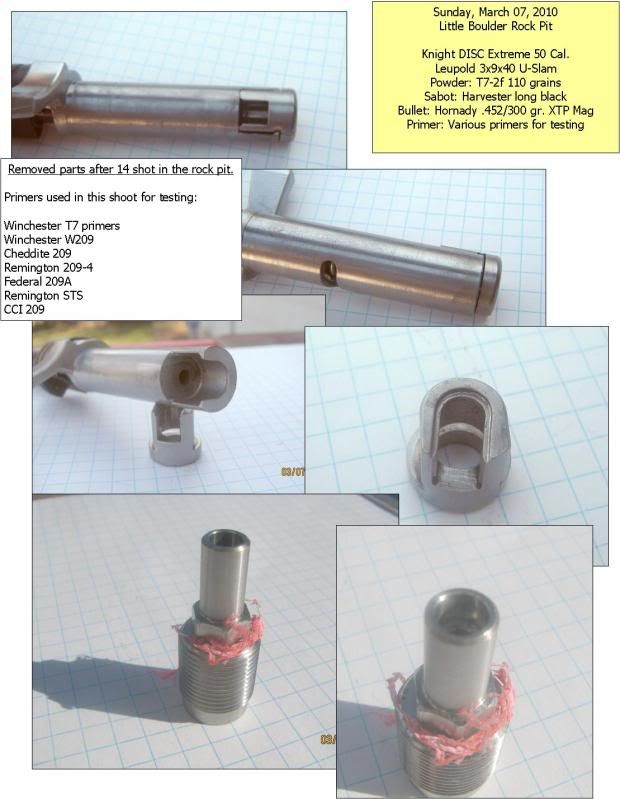

smokepole50In all of the BP's that I have drilled and installed the vent liner, the CVA plugs has been the easiest drilling metal by far. The Lehigh liner was designed originally with the Savage in mind and smokeless powder. It is hardened and will last even with the high end loads. I bet that puppy will work very well for you now... you will not even have to use the Mag primers. With the Lehigh I use W209's without any problem and very little cabon build up in the flash channel. I guess I am assuming you open the flash channel on the plug. The 3mm factory channel can plug fairly quickly especially with the high end loads. Might email Lehigh Dave and ask which metal he is using for his Knight conversion... what ever it is - it is amazing stuff... This is a Lehigh plug made for a Knight - this is really a good looking solid plug. Not much to clean them when they come out of the barrel looking like this.  At one time, Lehigh Dave told me the metal and the hardening process but I not a metal person so it went right over my head....

|

|

|

|

Post by GMB54-120 on Nov 19, 2010 0:08:47 GMT -5

smokepole50

I actually have a plug or 2 made from a grade 8 bolt. It mimics the Omega plug. No vent liner, head spaced and a rather deep powder side pocket with a fairly small flash hole by BH209 standards.

Works outstanding too.

I also like the modded CVA plug with a slightly larger flash channel and the Lehigh vent liner installed a little below flush. It works really well without head spacing or o-rings and Win209s.

No matter what you do to the plug though, the primer will still flow into the firing pin bushing slot/hole with those heavy loads. A custom bushing and possibly a smaller pin is the final part of the puzzle IMO.

|

|

|

|

Post by grouse on Nov 19, 2010 7:24:11 GMT -5

Well it's a done deal, the Lehigh vent liner is installed. I can not believe how soft the BP metal was when I drilled and tapped it! Smokepole50 You really cant expect any better with cheap guns. You will be happy with the vent-liner. |

|

|

|

Post by smokepole50 on Nov 19, 2010 11:18:32 GMT -5

Is there such a thing as a Nato 209 primer? I know CCI Nato-34 rifle primers have a thicker cup material for use in semi-auto rifles. I wonder if CCI 209 primers are any stronger??? Grouse, I agree with you but for the cost this CVA is a pretty good ML. In comparision, when I finish with my Rem.700 Custom, I will have spent enough money to buy (4) new CVA Accura's and that does not figure in the cost of the scope, scope base and rings. And I am doing most of the work! But it will be a all SS rifle and it might also be a switch barrel .308, that cost a bit extra..........  ) I set the vent liner height so that the dome is sticking out into the powder but I recessed it enough into the face of the BP so that the side of the VL screw dome, the area between where it goes from curved to the 82 degree angle, is setting down in a shallow step in the BP face. I figure this way I get just a little bit more surface area that the pressure has to flow past to reach the threads. Maybe it will help with the threads not getting so carboned up. The flash channel is .156 all the way back to the primer once you get past the VL. GMB54, That firing pin bushing is just brass! I wonder how long it will be before it starts to deform from the pounding and is hard to remove? A 304 SS model bushing using two holes at the edges to twist it into place might work better. Kind of like the Mauser recoil bolt nut. You could then make the firing pin and hole a bit smaller as well. How long is the firing pin? I have a mini lathe, some drill rod tempered should do the trick. Getting the screw made is another issue as I expect the threads are fairly fine. Smokepole |

|

|

|

Post by GMB54-120 on Nov 19, 2010 12:12:46 GMT -5

BINGO!

That is exactly the idea i have. That way there is no slot near the primer. IMO that is probably enough to keep the primer flow within reason.

BTW i have a custom plug that the vent liner pocket is larger than a 45cal bore...its about .469ish. That plug in a Accura 45 really ignites BH209.

I tried this design after using the Lehigh NFPJ conversion in my Elite 45. It's liner pocket is .500 and in the Elite 45, it was amazing. I would swear im getting more fps because it creates a bottle neck effect like a modern centerfire cartridge.

|

|

|

|

Post by smokepole50 on Nov 19, 2010 13:24:37 GMT -5

I was mistaken when I said the firing pin bushing was made of brass, it not. However it is flawed almost as bad by having a o-ring behind the shoulder. What idot though that one up?? If you made if rifle the right way in the first place you would not have to be concerned with primer blow back getting into the action around the firing pin bushing. Some bean counter did this to cut cost by having a cheap, as in not presision, firing pin bushing made and using a o-ring to take up the slop. Well guess what happens when all that pressure pushes back against the primer??? The primer pushes back, the o-ring behind the shoulder of the bushing compresses what ever amount the the bushing threads will allow and you get even more blow back. When my FP bushing is screwed all the way in the bushing is actually recessed in the action, add in a BP that is not the perfect length for a given primer and you have a lot of slop when the gun goes off. No wonder the primer is flowing back into the screw driver slot in the bushing, it is moving rearward at the same speed the bullet is going before it slams into that cheaply made and designed firing pin bushing. Grouse I am sure you are busting a gut right now and you are right, you get what you pay for. But why would CVA be so dumb after getting such a accurate barrel to go and cheap out small componets such as this. It makes no sence to me. I also now have gas cutting on the face of my firing pin bushing. It looks like a Mauser bolt face that has had 10,000 rounds fired in it. Well at least I have a project for the winter. My advice to you............don't buy a CVA if you want to shoot max loads, but then again, it probably will do the same thing at moderate loading if there is heavy bullet in the barrel.

Smokepole

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 19, 2010 15:15:16 GMT -5

primer brand are never the same size as eachother. its better to have a back up safety like the o ring than to have nothing. Smokepole, i think you are basically just full of crap, especially with the 60 shot BS , i got gas now cutting the face of my firing pin bushing! Im sure in your closet, under the white sheet is a knight you will pull out and praise  Man and to think my V1 Accura has well over 3,000 rounds through it now and on the original plug. Tisk Tisk. |

|

|

|

Post by smokepole50 on Nov 19, 2010 15:58:22 GMT -5

I can assure you I have no Knight ML in my closet or anywhere else! My cousin has one and that is it.........Prior to this CVA I have only owned T/C Muzzleloaders with the exception being one 54 cal Lyman Great Plains rifle.

I will gladly show you a picture of my firing pin bushing and let you see for yourself the off set ring that it has etched in its face. Pictures will have to wait until this weekend since I am at work presently. I only wish I had waited to install the vent liner so I could show you the erroded metal at the mouth of the BP primer shelf. The brand new .45 Accura will receive it's Lehigh upgrade tonight.

I really don't appreciate being called a liar, full of crap or whatever. I some times jump to conclusions but I always follow up buy admiting my mistakes, unlike some people.

I bought these TWO CVA Accura's because I believed CVA had finally got their act together and the accuracy of the Bergara barrel has been proven. You could not have given me a CVA ML 20 years ago, their workmanship was crap and their quality control sucked. However, it seems to me at present that there are still some forces present at CVA that think you can make parts cheaply and the public won't notice. Consumables are one thing and I can except the BP not lasting because I have been running this rifle at the upper end since the 3rd shot. The thing that bugs me the most is the lack of percision given to the critical part described above, the firing pin bushing. I see no problem with making a rifle with tight enough spec's to specify a certain primer type. We live in a world economy now, everyone can get Winchester 209 primers so why not make you rifle so there is ZERO head space with a given primer.

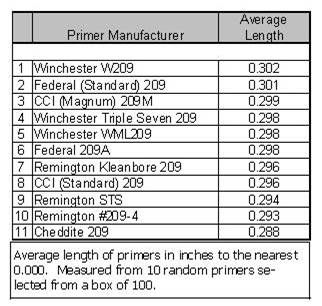

As I said above, I admit it when I possibly made a mistake. I need to measure some additional primers but when measuring a WIN 209 primer that I just bought in the BLUE packaging I see it measures .303 This could help with my issue as the other WIN 209 primers that I have been using packaged in Gray packaging and bought several years ago, and labled as Muzzle Loading primers measured .301. Like I said, I have only measure one of the 100 primers I just bought on the way into work but that .002 difference can not hurt.

Furthermore, to use a o-ring at the shoulder of the action firing pin bushing, the same bushing that supports the 209 primer is STUPID. If they can't make a receiver that is precice enough to also make a proper shoulder supported firing pin bushing that sets FLUSH with the face of the action so the BP can be made to set the primer tight against the action/firing pin bushing, then they need to go back to making side lock rifle.

Smokepole

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 19, 2010 16:11:01 GMT -5

send them to me then if they are that bad  |

|

|

|

Post by sabotloader on Nov 19, 2010 16:55:35 GMT -5

[bsmokepole50][/b] Do not know if this is anything you can use or not...  The other thing i am wondering about.... it seems to be the suggestion was to use a 'O' ring to adjust the head space on the primer. I question the smarts of this as instead of the pin holder being back ans snug against the block - would not the back pressure from firing the gun forse the holder back on to the 'O' ring in staed of an im-movable object? Seems like that would put a lot of stress on just the 'threads'. When you do the same thing with a Encore - i think the inserts that Bellum builds are a solid shim materail - which them would provide a positive solid stop... Does any this makes sense?  |

|

|

|

Post by smokepole50 on Nov 19, 2010 18:01:25 GMT -5

Yes, Shims would fix this issue. I will try and make some shims that take the place of the o-ring under the shoulder of the firing pin bushing. This should then make the bushing set flush with the face of the action when it is fully tightened in the action. It won't get rid of the screw driver slot and the primer might still flow into the slot but it will be a starting point to better support the primer. Ideally I would make another firing pin bushing without a slot so the brass part (cup) of the primer would be fully supported and be less likely to leak pressure.

I am not sure yet but I think I may also need some type of shim in the barrel to set back the BP a few thousands so the primer sets flush against the FP bushing. I still need to check the new WIN primers to see if they are even with the end of the barrel when placed in the BP.

Smokepole

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 19, 2010 19:01:57 GMT -5

try this, i THINK its a #4 washer. You just put that into the breech plugs primer pocket and that may be enough for a squeeze fit when you close the rifle up. You can also use a file to adjust a little at a time if its to much.

|

|

|

|

Post by sabotloader on Nov 19, 2010 22:24:52 GMT -5

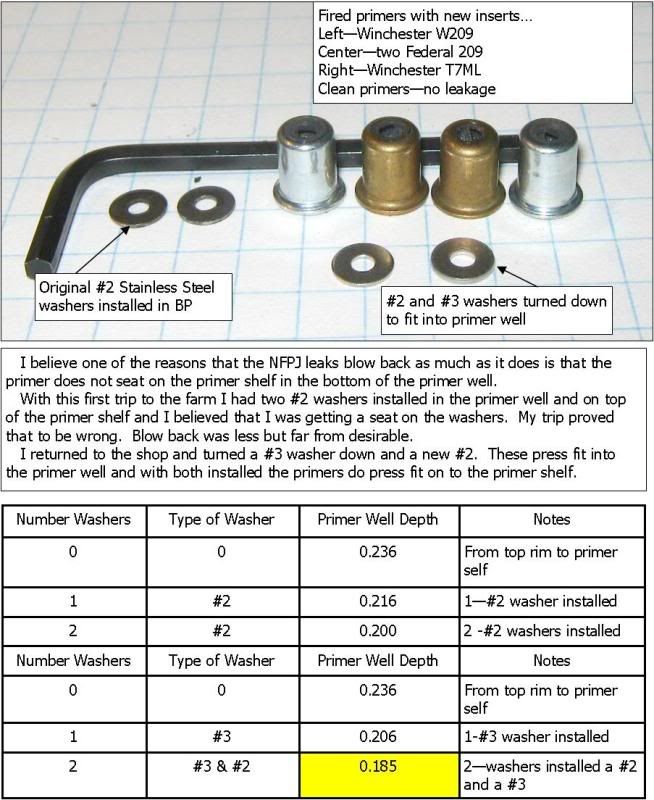

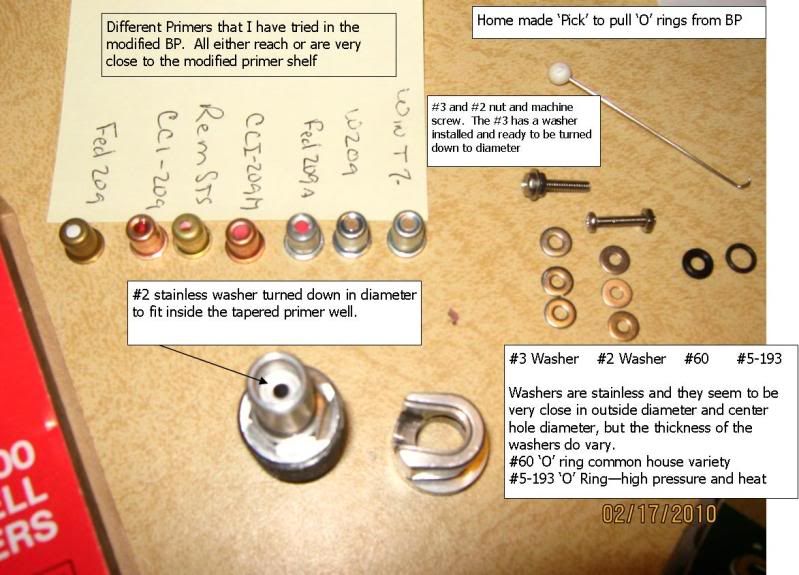

smokepole50I really think the shim thought is the way to go... Another thought is installing a shim in the 209 cup in the breech plug. If you can.... install a primer snugly in the breech plug ( i even tap it in gently to make sure it is seated on the primer shelf) and then with a feeler begin closing the action - hopefully you might get an idea of the gap so you can make a shim. I think that might have been what FG was getting at when he suggested a #4 washer. I ended up using a #2 and/or#3 stainless stainless washer... Here are some pics that show what I did...   This was for the Generation I Lehigh plug so kinda ignore the measurements.

|

|

|

|

Post by smokepole50 on Nov 19, 2010 22:29:44 GMT -5

Frontiergander, Thanks for the help, I will checkout the #4 washer idea. I would also like to bring up the issue again of the BP errosion. As I said in my first post, I had looked at the primer shelf under a microscope and it appeared that burnt metal was depositing itself on the BP surface that the face of the primer rest on. The material was very hard but I was a bit confused because the flash hole at the powder side seemed just fine at .031 as I mentioned above. After posting the first post I spoke with another member of the forum and he also thought it might be errosion so I went with that as a conclusion. At this point I am not 100% sure that it was not just very hard carbon with a bit of metal mixed in. Since looking at the new BP for the new .45 Accura I can see that the hole directly in front of the primer is much larger then the .031 area touching the powder. I had not noticed this when the .50 Accura was new because I was so set on getting it sighted in. So, as I said before, I admit when I may have been wrong and in this case I may have indeed jumped the gun so to speak in thinking the BP was shot out. I guess I failed to register your comment Frontiergander about it being carbon build-up because it vary well may have been just that. The drilling of the BP for the Vent Liner is the key evidence here as I saw what I thought was burnt and weak metal coming out with the drill and it was very possibly just the carbon build up being removed with the smaller drill bits I started the process with. I started drilling from the powder side and once I got threw the small flash hole area I started seeing black stuf that looked like cheap metal filings. SO........the more I think about it the more I think you were right. CVA BP's IMO are here by deemed worthy by ME. I jumped the gun but I was headed that way anyway because I had already bought 8 Lehigh vent liners, I just had not gotten around to doing it. To any and all who have read this post, always check for carbon build-up with a drill bit before you assume that what looks like errosion really is. I like my CROW cooked on the grill and medium rare............  ) |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 19, 2010 22:40:53 GMT -5

take your plug with you to the store, i am not exactly sure about the # size but thats one way to adjust that. I had a custom made plug made after i accidently sold a rifle with my accuras plug. Primer depth is a bit to deep and allows a lot of primer blow by but i most likely can fit it with the shim washer and some filing. I use winchester w209 primers and they are pretty filthy after only 3 shots, Carbon wise.  |

|

|

|

Post by smokepole50 on Nov 19, 2010 23:08:44 GMT -5

Thanks for all the ideas on the spacers. I will report back on what works with my rifle.

Smokepole

|

|